18 Years Factory Brown Aluminium Oxide to Malawi Manufacturers

Short Description:

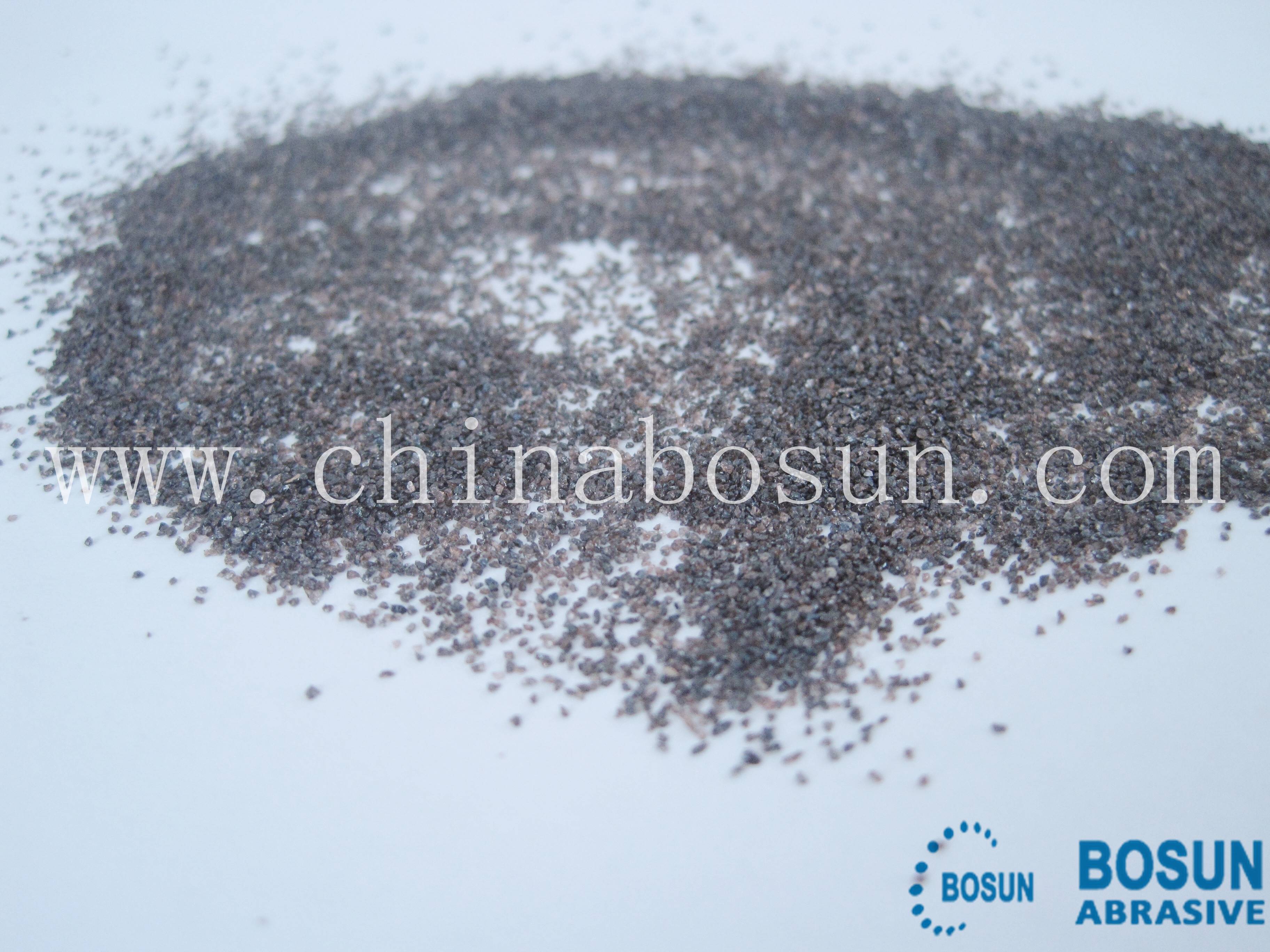

FEATURES Brown aluminium oxide is fused and crystallized under high temperature from a mixture of bauxite and other and other raw materials. It is characterized by its high hardness,good toughness and shape in size. Abrasives tools made of it are suitable for grinding metals of high-tensile strength such as: carbon steel,general-purpose alloy steel,annealed malleable iron and hard broze,etc.It also can be used as refractory materials. Grit size :12#-220#; Micropowder: 240#-1200#. Character 1....

18 Years Factory Brown Aluminium Oxide to Malawi Manufacturers Detail:

FEATURES

Brown aluminium oxide is fused and crystallized under high temperature from a mixture of bauxite and other and other raw materials. It is characterized by its high hardness,good toughness and shape in size. Abrasives tools made of it are suitable for grinding metals of high-tensile strength such as: carbon steel,general-purpose alloy steel,annealed malleable iron and hard broze,etc.It also can be used as refractory materials.

Grit size :12#-220#;

Micropowder: 240#-1200#.

Character

1. AL2O3 95% SIO2 1.5% ;

2. Fe2O3 0.3% TIO2 3.0% ;

3. Hardness(mohs) 9 ;

4. Ture density 3.9 ;

5. Magnetic material content 0.050%.

TECHNICAL DATA

|

Purpose |

Specification |

Chemical Composition(%) |

Magnetic material content(%)max |

||||

|

Abrasives grade |

Al2O3min |

Fe2O3max |

SiO2max |

TiO2max |

|||

|

grain |

12-80 |

95 |

0.3 |

1.5 |

3.0 |

0.05 |

|

|

90-150 |

94 |

0.3 |

1.5 |

3.0 |

0.03 |

||

|

180-220 |

93 |

0.3 |

1.5 |

3.5 |

0.02 |

||

|

micropowder |

240-4000 |

92.5 |

0.5 |

1.8 |

4.0 |

— |

|

|

Refractory grade |

Group Size |

0-1mm 1-3mm 3-5mm 5-8mm |

94.5 |

0.3 |

1.5 |

3.0 |

— |

|

Fine Powder |

-180mesh -200mesh -240mesh -320mesh |

93.5 |

0.5 |

1.5 |

3.5 |

— |

|

|

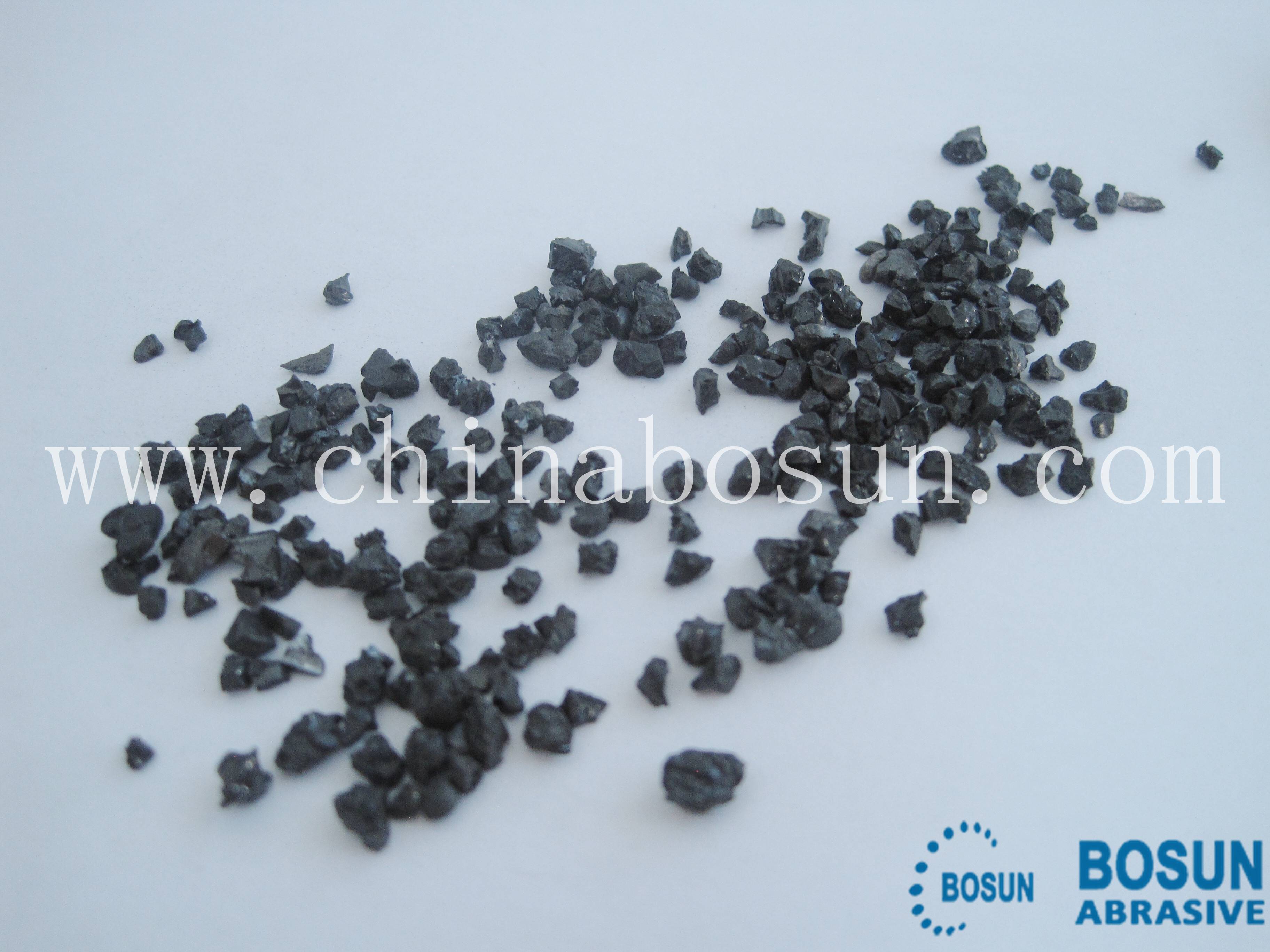

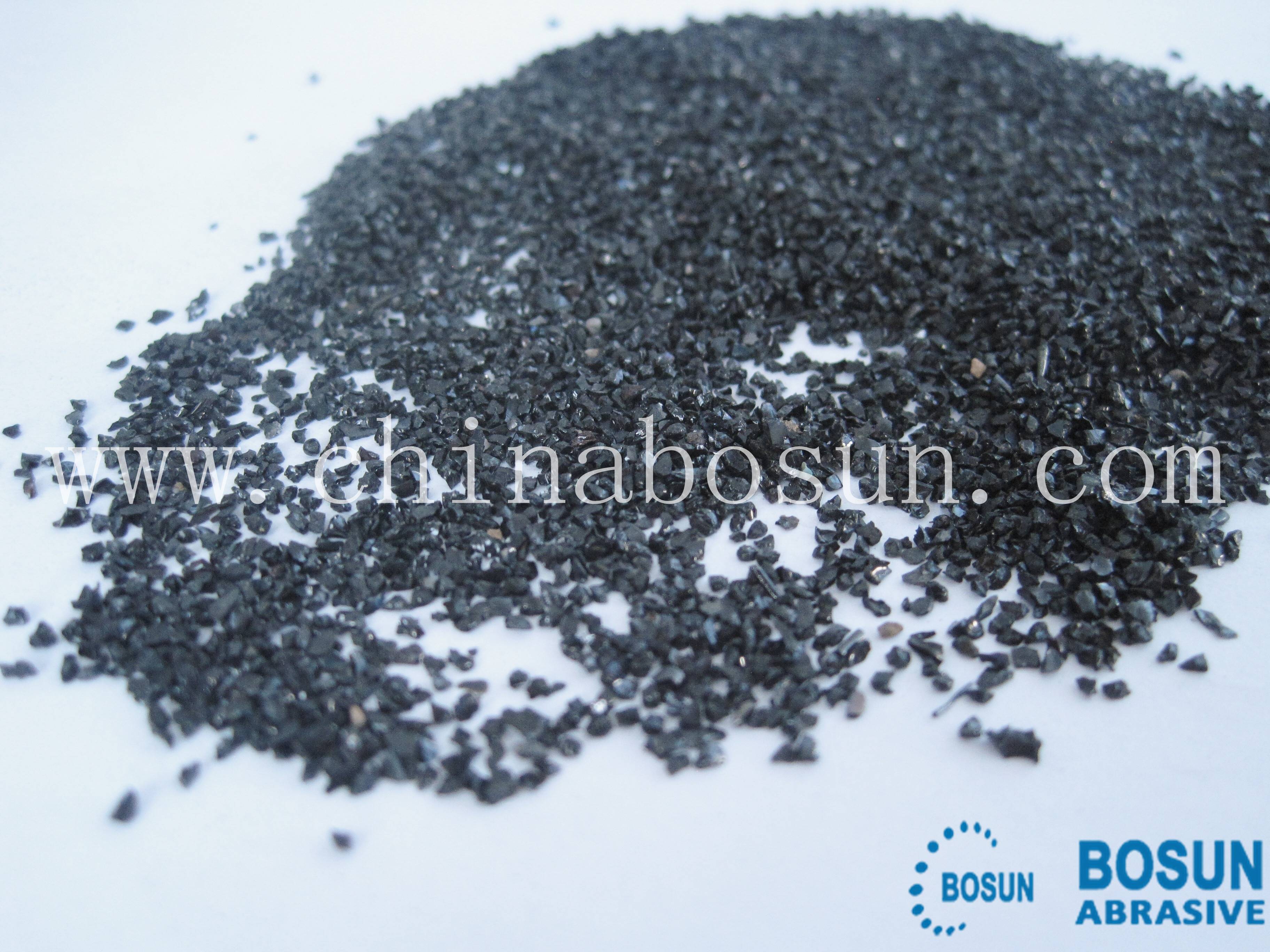

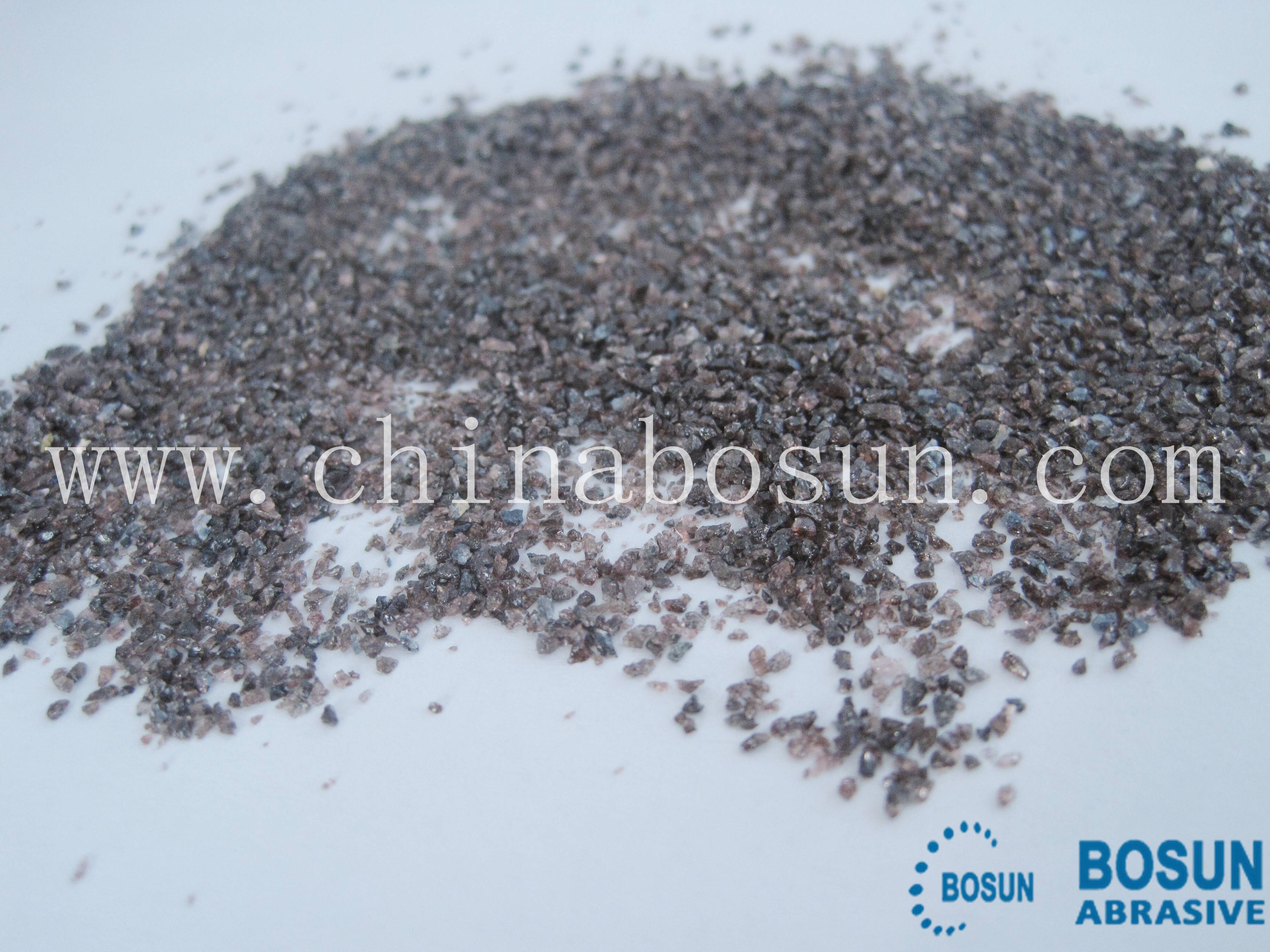

color |

Dark brown |

||||||

|

Hardness(mohs) |

9.0 |

||||||

|

Melting point(°C) |

2250 |

||||||

|

Maximum service temperature(°C) |

1900 |

||||||

|

Ture density(g/cm3) |

3.9 |

||||||

|

Crystal form |

Trigonal crystal system |

||||||

APPLICATION

Product usage

1) Abrasive: Produce ceramic gring wheel, resinoid gringding wheel, Grinding stone, Gringing block, sand paper, sand cloth, sand belt, polish wax, abrasive paste, coating etc..

2) Refractory material: Mainly used for abrasion and high temperature resiatant, inoxidizable aggregate and filling of shaped and monolithic refractory in steel metallurgy, various industrial stoves, electric furnace etc..

3) Sandblasting abrasive: Mainly used for various material workpieces to decontaminate, derusting, prevent corrosion, remove oxide skin etc..

4) Abrasion resistance ground: Mainly used for non-slip of airport and road, chenmical factory

board paving.

5) Precision casting: Investment casting technics of stainless steel and aluminium casting in coating.

Application

1. it are suitable for grinding high-speed,high carbon steel

2.high-grade refractory materials

3.abrasives tool

4.grinding and polishing

5.ceramics

6.LED

7.sandblasting

8.aviation

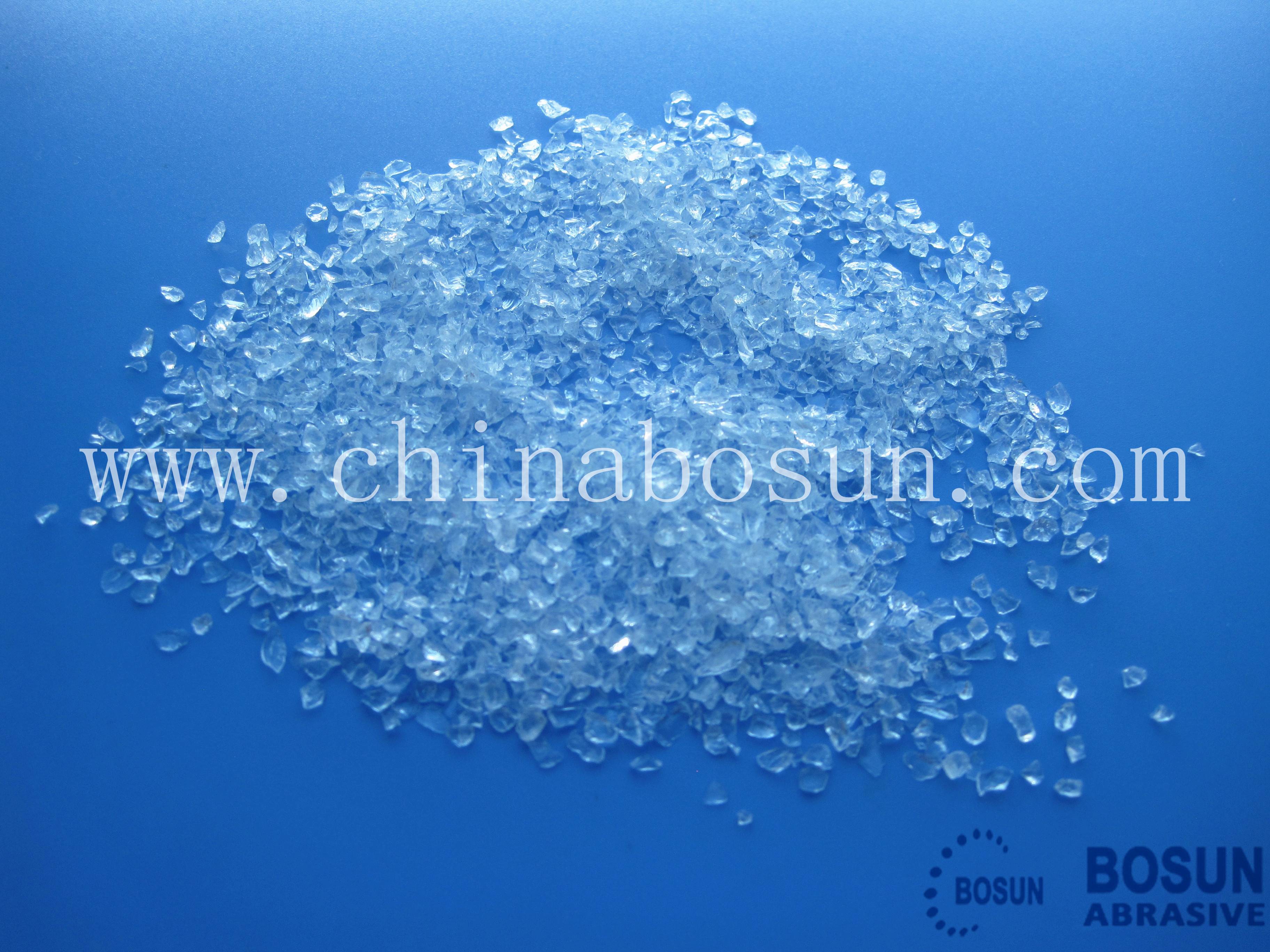

Product detail pictures:

Related Product Guide:

Benefits of Garnet Abrasives

Basic Information About Abrasive Garnet Processing

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for 18 Years Factory Brown Aluminium Oxide to Malawi Manufacturers, The product will supply to all over the world, such as: kazan, Paris, Philippines, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We are able to also offer you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and products, please speak to us by sending us emails or call us quickly. In an effort to know our products and company extra, you may come to our factory to view it. We will generally welcome guests from all over the world to our business to create business relations with us. Please feel cost-free to speak to us for small business and we believe we'll share the best trading experience with all our merchants.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.