Popular Design for Black Silicon Carbide for Argentina Factory

Short Description:

FEATURES Silicon carbide is made from quartz sand, petroleum coke (or char), sawdust from electric arc furnace smelting. In nature there are also rare silicon carbide mineral moissanite. Silicon carbide, also known as Moissanite. In contemporary C, N, B and other non-oxide refractory materials in high-tech, silicon carbide is the most widely used and most economical one. Can be called emery or refractory sand. Silicon carbide is with quartz sand, petroleum coke (or coal tar), wood (green sili...

Popular Design for Black Silicon Carbide for Argentina Factory Detail:

FEATURES

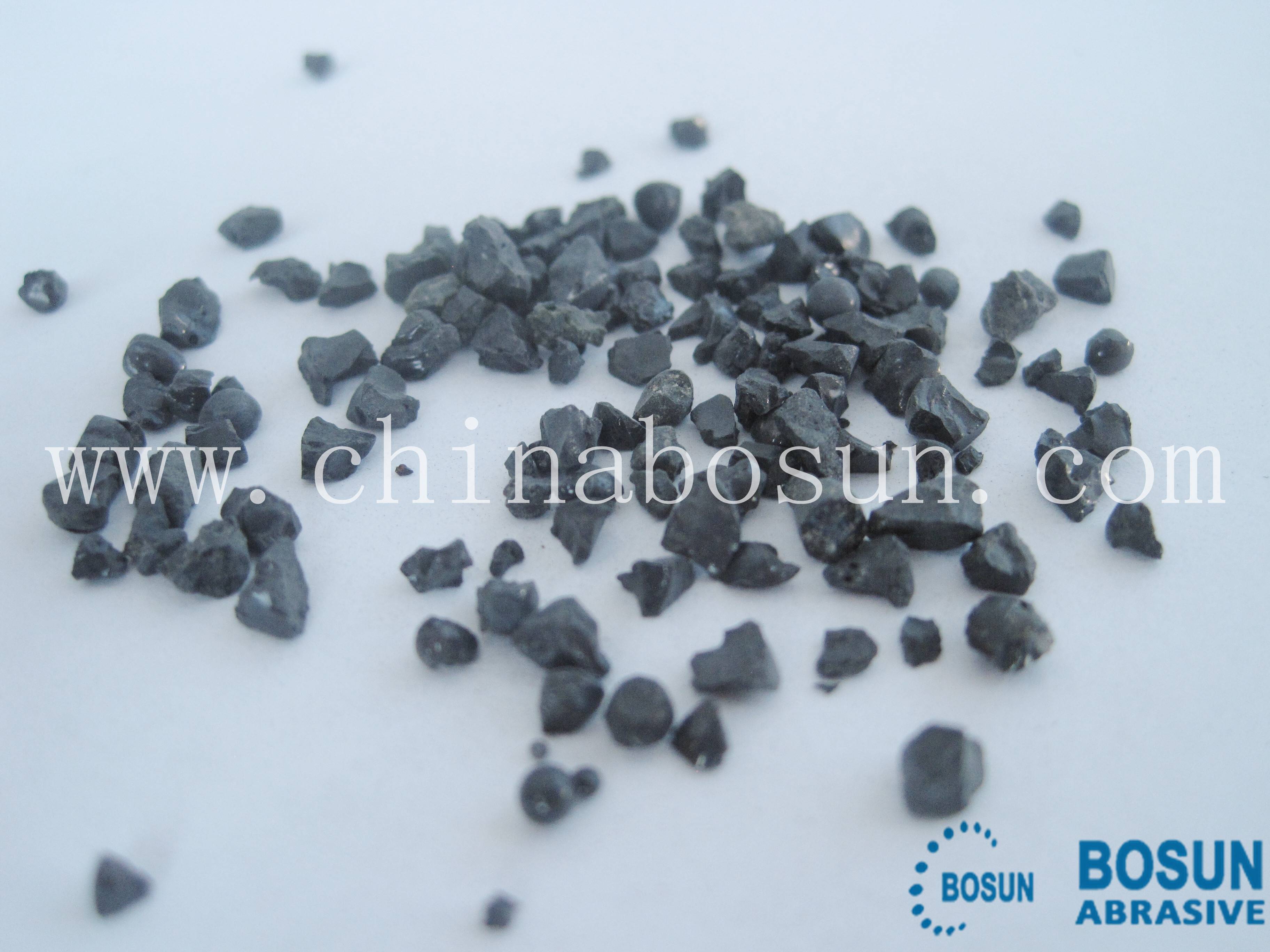

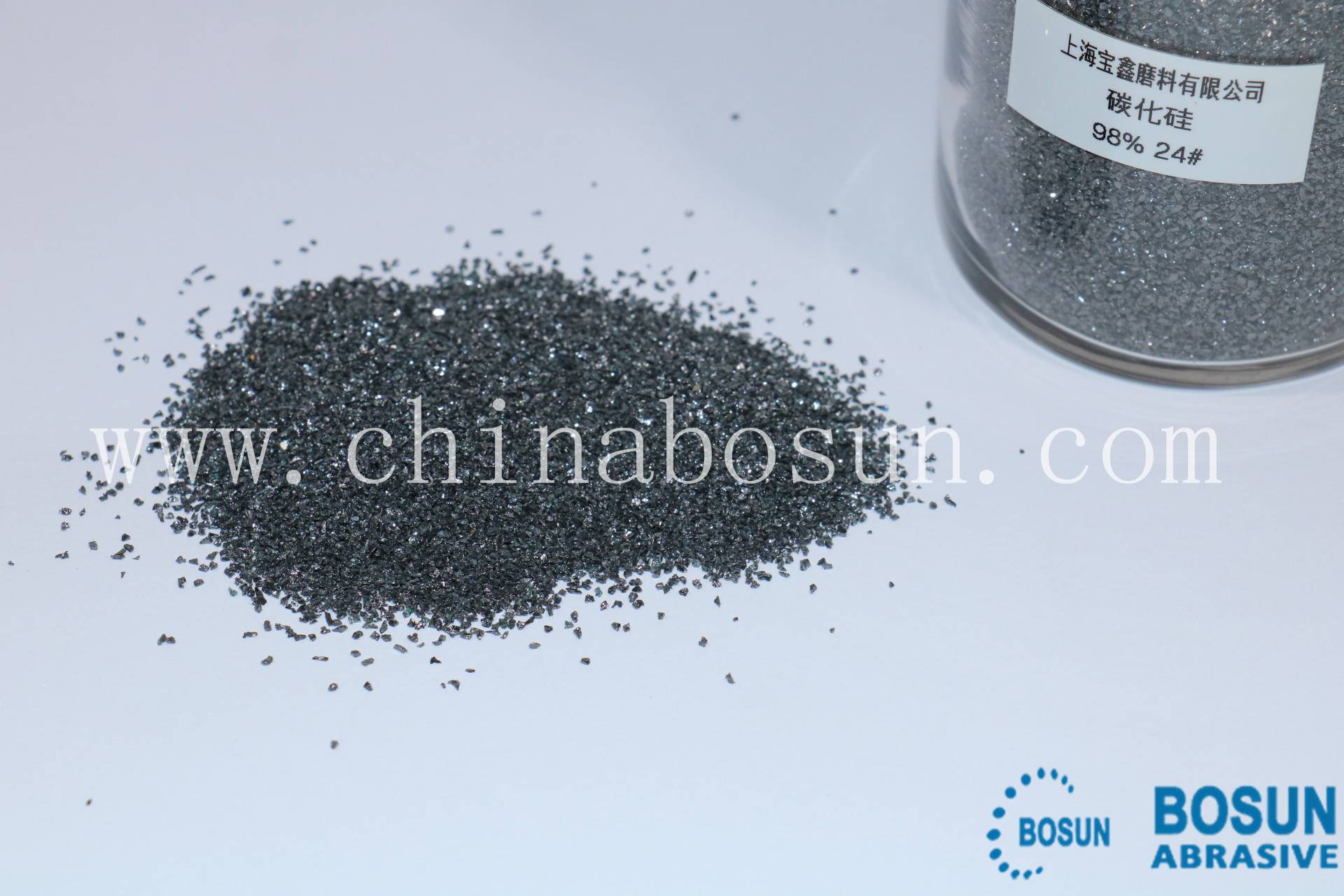

Silicon carbide is made from quartz sand, petroleum coke (or char), sawdust from electric arc furnace smelting. In nature there are also rare silicon carbide mineral moissanite. Silicon carbide, also known as Moissanite. In contemporary C, N, B and other non-oxide refractory materials in high-tech, silicon carbide is the most widely used and most economical one. Can be called emery or refractory sand. Silicon carbide is with quartz sand, petroleum coke (or coal tar), wood (green silicon carbide need to increase the production of salt) and other raw materials in high temperature resistance furnace smelting. At present China’s industrial production of silicon carbide is divided into two kinds of black silicon carbide and green silicon carbide, are hexagonal crystals, accounting for 3.20 to 3.25, microhardness 2840 ~ 3320kg/mm2

Grit size :12#-220#;

Micropowder: 240#-1200#.

Character

SIC 88%-97%,

Fe203 2.5% max,

F.C. 2.5% max,

Moisture 1.0% max.

TECHNICAL DATA

|

Size Range |

SiC ≥ |

Free carbon ≤ |

Fe2O3% ≤ |

|

|

Black silicon carbide |

12 # -90 # |

98.5 |

0.2 |

0.6 |

|

100 # -180 # |

98 |

0.3 |

0.8 |

|

|

220 # -240 # |

97 |

0.3 |

1.2 |

|

|

Green Silicon Carbide |

20 # -90 # |

99 |

0.2 |

0.2 |

|

100 # -80 # |

98.5 |

0.25 |

0.5 |

|

|

220 # -240 # |

97.5 |

0.25 |

0.7 |

|

|

W63-W20 |

97 |

0.3 |

0.7 |

|

|

W14-W10 |

95.5 |

0.3 |

0.7 |

|

|

W7-W5 |

94 |

0.3 |

0.7 |

|

APPLICATION

Product usage

1. as an abrasive, can be used for abrasives, such as grinding wheel, Whetstone, grinding, sand tile and so on.

2. as metallurgical deoxidizer and high temperature materials.

3. high purity single crystal can be used for the manufacture of semiconductor manufacturing silicon carbide fibers.

4. The modifiers can be used as a deoxidizer and a steel the cast iron structure, used as starting materials for making silicon tetrachloride, are the main raw materials of silicone resin industry.

5. High-temperature materials for indirect heating

Use for Large blast furnace lining

Application

1.Ceramics,

2.advanced refractories,

3.abrasives,

4.metallurgical raw materials,

Product detail pictures:

Related Product Guide:

Low Cost Synthesis of Silicon Carbide and Silicon Nitride

Benefits of Garnet Abrasives

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Popular Design for Black Silicon Carbide for Argentina Factory, The product will supply to all over the world, such as: Finland, Jakarta, Tunisia, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.